Folks, buckle up because today we’re diving deep into the powerhouse concept that’s been revolutionizing the manufacturing game – the Visual Factory. Enter a dynamic, efficient production floor where information flows like a well-oiled machine, and everyone’s on the same page without skipping a beat.

So, what’s the big deal with visual factory, you ask? At its core, it’s all about using visual tools and cues to communicate, well, everything. From the status of production processes to the nitty-gritty details, if you can see it, you can conquer it.

So, if you’re ready to take a journey into the heart of modern manufacturing efficiency, where visuals reign supreme, and lean principles get a turbo boost, then you’re in for a treat. Welcome to the world of visual factory optimization in modern manufacturing – where clarity meets productivity, and every glance holds a nugget of valuable information. Let’s roll.

Key Elements of a Visual Factory

Alright, get ready as we dissect the fundamental components of a Visual Factory – the magic formula that transforms an ordinary manufacturing setup into a finely tuned efficiency powerhouse.

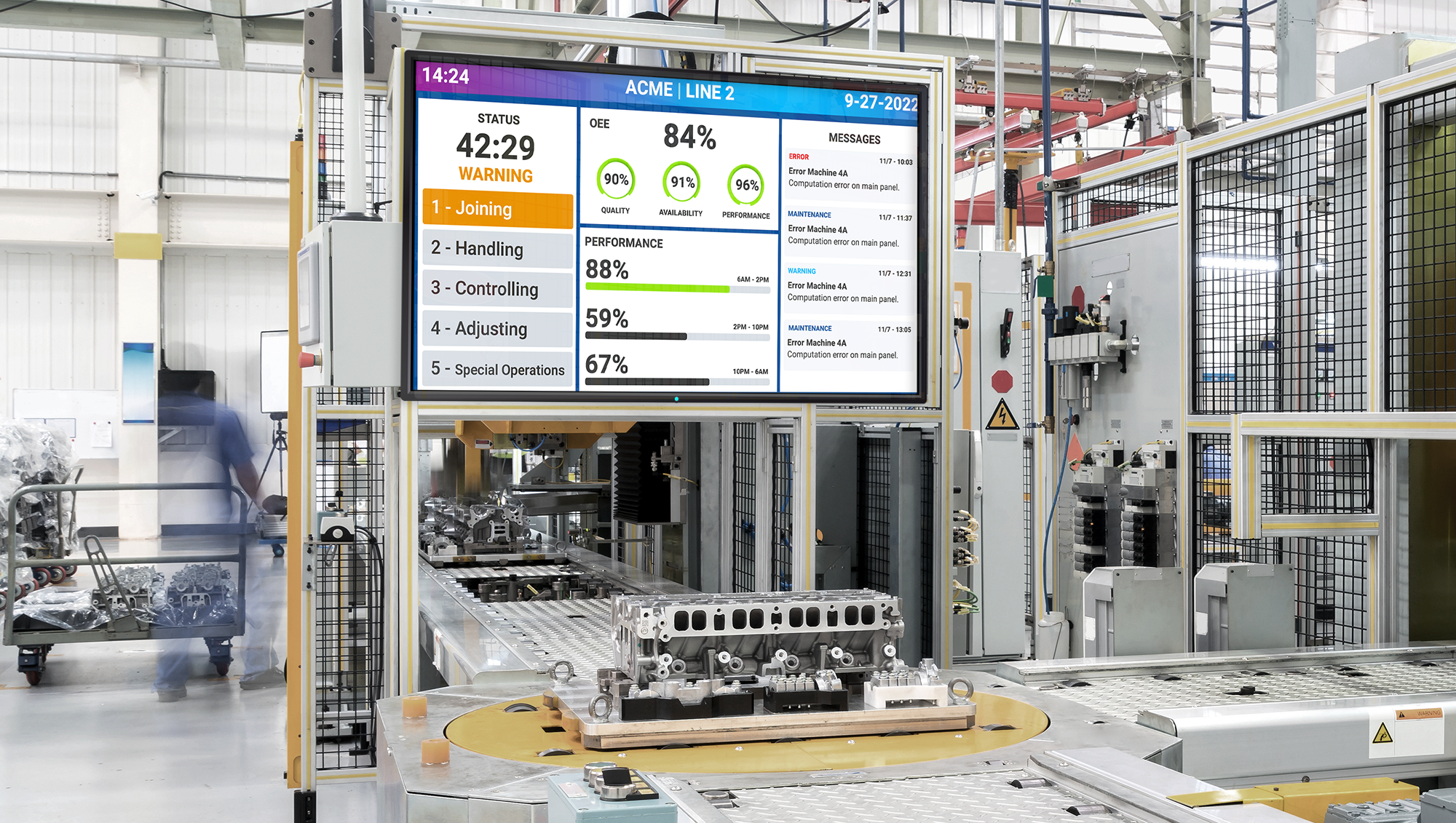

- Visual Management: Visual Management is at the forefront of our visual factory toolkit. It utilizes charts, graphs, and clear visual cues to communicate the story of your production status in a language that everyone can easily understand. No more decoding complex symbols –everything is presented plainly for straightforward comprehension.

- Color Coding: Enter color coding, the rockstar of simplicity. Think of it as your manufacturing floor’s very own rainbow language. Materials, processes, heck, even the coffee machine – color-coded for quick recognition. Red means stop, green means go – life’s simpler in color, my friends.

- Visual Controls: Now, let’s talk Visual Controls – the traffic lights of manufacturing. They’re your indicators, your alarms, your “hey, pay attention!” cues. When something’s off, the Visual Controls light up, steering you away from potential hiccups before they even happen. It’s like having a co-pilot that never takes a coffee break.

- Andon Systems: These bad boys are the screamers of the factory floor, signaling when things aren’t quite right. A red light, a buzz, and voila – your team’s on it like white on rice, resolving issues before they even think about becoming problems.

- Standardized Work: Imagine a world where every task follows a set standard, like a choreographed dance. It’s not chaos; it’s a well-rehearsed routine that keeps things humming along smoothly. Standardized Work ensures everyone’s on the same page, every step of the way.

- 5S Principles: Let’s talk about the 5S Principles – Sort, Set in order, Shine, Standardize, and Sustain. It’s about decluttering, organizing, and creating a workspace where chaos goes to die. From tools to workstations, the 5S Principles ensure everything has its place, and everything’s in its place.

- Safety Visuals: Last but certainly not least, Safety Visuals – the unsung heroes of workplace well-being. Think of them as the guardian angels of your manufacturing floor, guiding everyone safely through potential hazards. Whether it’s a “watch your step” sign or a vivid reminder to gear up, safety visuals ensure your team stays safe while rocking the production game.

In a nutshell, these key elements aren’t just cool concepts, they’re the gears that keep the visual factory engine humming. They turn complexity into clarity, chaos into choreography. Stay tuned, because we’re just scratching the surface of how these elements bring the Visual Factory to life.

The 8 Key Benefits of Visual Factory in Manufacturing

- Enhanced Communication: Visual Factory fosters instant communication across all manufacturing levels.

- Improved Efficiency: Visual cues and displays quickly identify and resolve inefficiencies, boosting overall efficiency.

- Reduced Errors and Waste: Visualizing standardized processes minimizes errors and waste in manufacturing.

- Employee Empowerment: Visual Factory provides clarity, fostering job satisfaction and motivation among employees.

- Quick Issue Response: Visual controls, including Andon Systems, rapidly detect and address issues, minimizing downtime.

- Consistent Quality: Standardized Work and 5S Principles maintain consistent quality standards on the production floor.

- Enhanced Safety: Safety Visuals ensure a safe working environment through clear communication of safety protocols.

- Increased Productivity: Improved communication, streamlined processes, and continuous improvement result in heightened productivity across the manufacturing cycle.

The Role of Digital Signage in Developing a Visual Factory

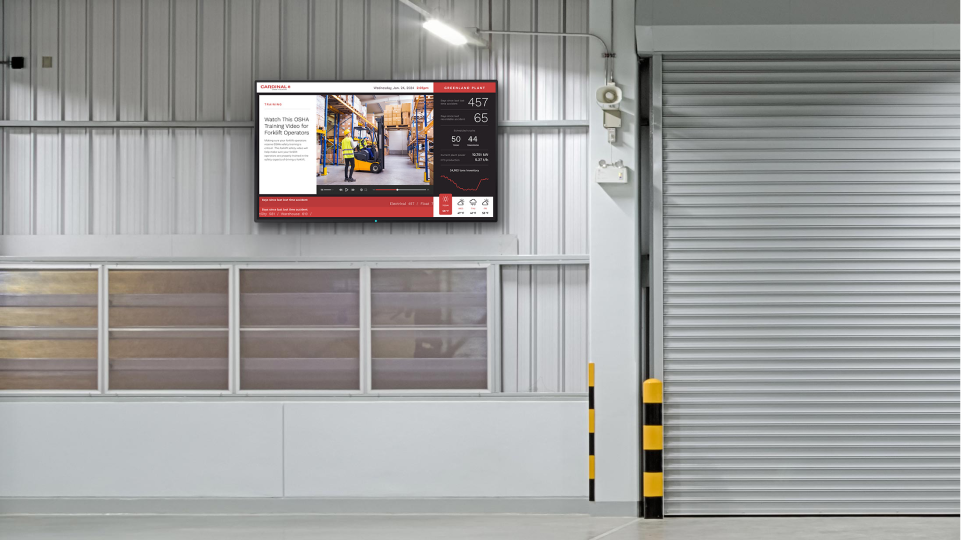

Real-time updates, visually compelling displays, and seamless information delivery have become the new norm in today’s modern factories. It’s more than just conveying data; it’s about delivering impactful messages that capture attention and motivate the workforce.

Here’s where digital signage steps into the spotlight as a versatile and dynamic solution for transforming communication within a visual factory environment. Manufacturing signage is a conduit for real-time, engaging, and impactful information delivery, revolutionizing the way data is presented and absorbed on the manufacturing floor.

Now, let’s talk integration. Digital signage seamlessly weaves into the fabric of a visual factory through its integration of Supply Chain Management (SCM), Warehouse Management Systems (WMS), Andon Systems, and beyond. Picture real-time production metrics, supply chain updates, warehouse status, and even On-the-Job training modules, all presented dynamically on a digital canvas.

Enhanced visibility of crucial information, reduced response time to issues, heightened employee engagement and safety are just the beginning. By seamlessly integrating digital signage with visual factory applications, digital signage becomes a catalyst for efficiency, fostering a proactive and informed workforce.

Transforming Tomorrow’s Manufacturing Today

In manufacturing today, the visual factory is the backbone of efficiency and clarity. The key elements we’ve explored here aren’t just concepts; they are the driving force propelling manufacturing into a streamlined future.

Ready to modernize your operations? Connect with the Korbyt Solutions team. Explore how digital signage can reshape your visual factory initiatives. It’s not just about technology; it’s a partnership propelling your manufacturing into a more informed, connected, and efficient era.

Let’s shape tomorrow’s manufacturing landscape, today.